17th February 2026

Happy Lunar New Year.

According to the Chinese horoscope, 2026 is the Year of the Fire Horse. This symbol is one of the most energetic in the Chinese zodiac and promises dynamic strength, momentum and creative power.

We want to harness this energy to work with our partners and customers worldwide to expand our business relationships and make this a successful year together.

With this in mind, we wish all our business partners and customers worldwide, but of course especially in China and Asia, a healthy, happy and successful 2026 – the Year of the Fire Horse.

29th January 2026

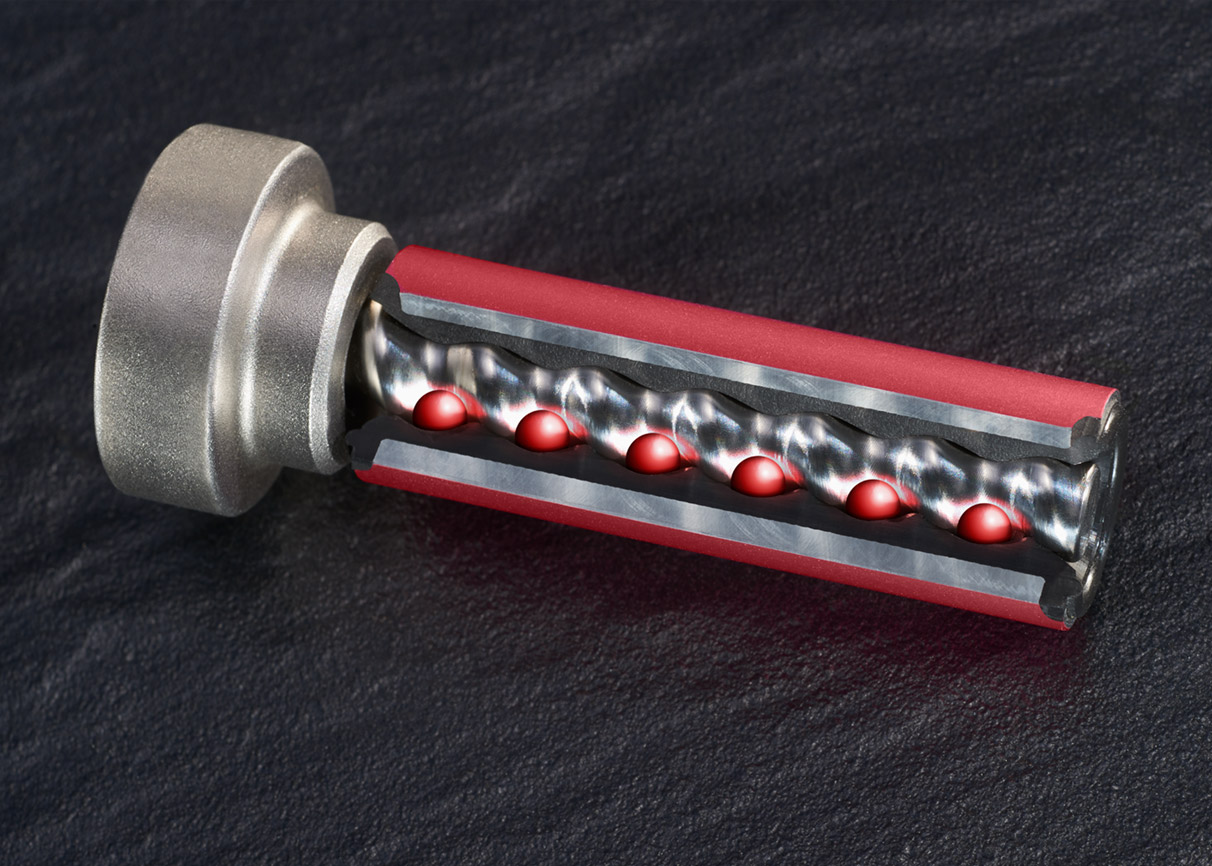

VISEC components - put through their paces

Before new developments of dosing components from VISEC (rotor, stator, shaft seals) can be officially released and sold, they must undergo numerous internal test series and validation processes. These consist of standardised methods as well as specific guidelines and specifications adapted to the new products and market requirements.

These elaborate processes guarantee and maintain the high-quality level of VISEC products. This results in perfect dosing accuracy, maximum precision and repeatable dosing results.

In general, new components are first installed in sample pumps in the VISEC technical centre and the accuracies and deviations are determined. Two different test media are used: an aqueous solution (low viscosity) and a standardised material with high viscosity and abrasive ingredients (mixture of high-viscosity grease with metal powder) as a second test medium. If new components pass these hardness tests in these extreme ranges, the next step follows: depending on the application and product, specific test series are carried out. In the case of a new sealing ring, for example, this can be an endurance test with changing dosing direction, or tests with different dosing pressures or dosing speeds.

Very specialised validation processes can also be defined for specific applications, e.g. thermal paste dosing with new stator elastomers. These include endurance tests to determine the respective stator abrasion or general service life tests.

All test results are then analysed and assessed and, if necessary, adjustments are made to the products very flexibly and quickly. These modifications are then checked again in trials and test series and the new products are only released once they have passed.

However, once the new products have been officially released and sold to customers, this is not the end of product monitoring: through ongoing feedback and dialogue with customers, data and information are analysed and corrections applied where necessary in order to continuously improve the products.

Through these measures, VISEC guarantees the high-quality level of the products and satisfied customers.

SEC / VISEC wishes you a Merry Christmas and a Happy New Year 2026

‘The best way to make yourself happy is to try to make someone else happy.’ – Mark Twain

The year is slowly drawing to a close and Christmas is just around the corner. It's high time to escape the exciting but hectic working day and find some peace and quiet.

Take advantage of the break and enjoy a relaxing holiday with your family so you can start 2026 with a spring in your step.

We would like to thank all our customers and business partners for their trust and successful cooperation this year and send you our warmest Christmas greetings.

Your SEC / VISEC team

22nd October 2025

VISEC – Special cleaner for dosing components

StaRo CLEANER

Many users of dosing systems face the challenge of adequately cleaning the individual components during maintenance work, process changes or material changes. In most cases, either cleaning agents that are chemically very aggressive and therefore hazardous to health, e.g. isopropanol, acetone, etc., or, on the other hand, ‘mild’ cleaners are used, which, however, often do not deliver the desired cleaning results.

Thanks to its chemical expertise and experience, VISEC has developed the ideal cleaner for dosing components. Originally intended exclusively as a cleaner for VISEC dosing components (rotor, stator, shaft seals for eccentric screw dispensers), StaRo-Cleaner very quickly established itself as a universal cleaner for other dosing systems and technologies as well.

The StaRo-Cleaner solvent cleaner is glycol ether-based and is suitable as a high-performance cleaner for all work tools or dosing components. It is particularly suitable for the optimal cleaning of VISEC stators with the hi-act, hi-per and hi-pro compounds.

The components to be cleaned (such as rotors and stators) are immersed in the cleaner at room temperature, or simply sprayed or brushed with it. After a few minutes, the surface to be treated can be cleaned by simply wiping it down.

StaRo CLEANER is harmless to health and is not classified as a hazardous substance. There is no need for complex protective measures such as extraction systems or protective equipment, and the cleaner can be used without hesitation.

Since StaRo CLEANER is not a hazardous substance, it offers the additional advantage that transport can be arranged easily and without major restrictions.

The cleaner is available in 250 ml bottles.

VISEC has developed an innovative cleaner to complement its dosing components, offering customers a comprehensive range of benefits. The dosing process is considered as a whole, and users are provided with concrete solutions and assistance.

07th August 2025

Equipped for the megatrends of the adhesives industry: The progressive cavity technology

Many industrial customers and companies demand specific and highly specialised adhesives from adhesive manufacturers that offer the best properties for a particular application. It is necessary to use flexible dosing solutions that can apply these specialised adhesives reliably and precisely.

Another trend describes smart production: dispensing systems should be fully embedded in the process to increase efficiency and minimise downtime (e.g. due to unforeseen maintenance work, malfunctions, etc.). Integrated sensors (such as pressure, temperature or flow sensors) in combination with AI guarantee undisturbed production processes and optimised maintenance cycles through predicted maintenance.

In the field of micro-electronics, the requirements are moving towards even smaller dosing quantities with functional adhesives. These must, for example, bond sensitive or dissimilar materials, control heat dissipation, insulate or conduct electricity and equalise and dampen shocks or vibrations. Of course, the requirements for dispensing technology are also closely linked to this: the highly complex adhesives must be dispensed precisely, repeatably and reliably.

As a result of initiatives in the EU and worldwide, the topic of sustainability is playing an increasingly important role in the field of adhesive technology and adhesives.

These should, for example, contain as few harmful substances as possible, be solvent-free and be used as sparingly as possible. The consumption of adhesives should be minimised and designed to conserve resources. Over- and incorrect dosing, waste material and excessive residual quantities in containers should be prevented.

Progressive cavity technology offers the perfect answer to these requirements and trends:

Dispenser and dosing systems with the progressive cavity principle offer highly precise, reliable and repeatable dosing results.

This, as well as the economical use of resources and energy, can significantly minimise adhesive waste and implement the issue of sustainability. This is also guaranteed by the completely clean dispensing (pull-back and no dripping from the dispensing systems). Residual quantities in containers are extremely reduced through the use of drum emptying systems with progressive cavity pumps (less than 1 % residual quantity).

Specialised and functional adhesives can also be applied to micro-electronic components with process reliability and precision, providing the perfect solution for this challenge. High-viscosity media with abrasive fillers are also perfectly suited to this dispensing technology.

Simple control - guaranteed dispensing volume per revolution - allows these systems to be easily integrated into a smart production environment. Intelligent servo drives, in combination with various sensors, offer an optimised and safe process design and landscape.

The dosing process for liquid adhesives is thus transformed from an ‘uncertainty factor’ in production to a ‘stability anchor’ in industrial production.

VISEC develops and manufactures innovative dosing components (e.g. rotor, stator, sealing rings) for progressive cavity dispensers and offers customers a perfect environment for designing and developing their own dosing systems. VISEC provides support not only with high-quality components, but also with expertise in the field of dosing.

30th June 2025

VISEC - a permanent fixture in the dosing market

VISEC dosing components have been on the market for more than six years now. VISEC has clearly established itself as a brand that stands for the highest quality, reliability and innovation and has enjoyed an unrivalled success story.

Since its market launch, VISEC has gradually and continuously expanded its product portfolio with innovative products and continues to focus on development, flexibility and quality.

The existing micro and standard dosing product series (D and R series) have been supplemented with additional sizes, and completely new and innovative products have been developed. Examples of this include the VISEC shaft sealing rings and the unique dosing geometry of size 2R12-4eQ.

VISEC is trusted by countless customers worldwide and is always the first point of contact when it comes to the development of progressive cavity dispensers. VISEC has also evolved from a pure manufacturer of dosing components to a competent system partner in the field of dosing technology. VISEC supports its customers with its know-how and expertise and is on hand with help and advice.

At the same time, production capacities were gradually expanded in order to be able to provide high quantities in consistent quality on demand and offer the shortest possible delivery times.

VISEC will not stand still and rest in the future, but will continue to advance progressive cavity technology and develop innovative and new products. There are already many interesting products in the pipeline - you can look forward to them.

11th April 2025

Anaerobic adhesives – best dosing solution with VISEC components

The use of anaerobic adhesives has become increasingly popular in all manufacturing applications, such as consumer, electronic, automotive or general industry. In the past, the main reason to use anaerobic glue was to increase the seal or holding force of mechanically joined connections such as thread lockers, thread sealants, or flange sealings. Anaerobic adhesives remain liquid until isolated from oxygen in the presence of metal ions, such as iron or stainless steel. For example, when an anaerobic adhesive is applied between a nut and a bolt on a threaded assembly or screw thread, it rapidly starts to cure or harden to form a stable crosslinked plastic with a strong adhesion to many metals. The shear strength of this gluing connection is very high.

Typically, anaerobic adhesives are used to lock threaded assemblies together. Here, they prevent loosening and corrosion of the fastener, maintain proper clamping force, and offer controlled torque for removal of the assembled parts. Anaerobic gasketing materials are commonly used as formed-in-place gaskets (FIPG) that produce leakproof seals between flanges. At fixed cylindrical assemblies, such as joining a bearing onto a shaft, anaerobic adhesives known as retaining compounds enable manufacturers to glue these parts that once could only be assembled using press fits or shrink fits.

When it comes to the best suitable dispensing and dosing equipment, there could be many mistakes and wrong systems to be used. The main issue is, when metal parts are used inside the dosing systems, so – by definition – the anaerobic adhesive starts to cure at these metal parts. Passivation of these metals parts is one possibility to avoid this curing effect, but this process means additional costs, requires careful handling (damage of passivation layer) and also needs a renewal of this passivation process after some time.

VISEC has developed a system that is perfectly suited to dosing and processing an-aerobic adhesives without any problems. This system solution finally makes it possible to integrate this type of adhesive safely, reliably and with repeat accuracy in the production process.

In general, the PCP-technology offers a precise and accurate solution (accuracy and repeatability of +/- 99% could be guaranteed). The adjustable suck-back of the dispenser offers a clean solution, even for dosing of anaerobic.

As of now an automatic & process safe dispensing solution for anaerobic glue could be offered, this help to reduce production costs and increase the yield and efficiency of the production by decreasing the cycle times.

Stable and reliable processes mean cost and time savings

Contact our sales team for more information (info@sec-compounds.com). We look forward to hearing from you.

17th February 2025

Trade fair: PRODUCTRONICA China 2025

https://www.productronicachina.com.cn/en/

26 - 28 March 2025, SNIEC, Shanghai

New VISEC innovations presented by SHENZHEN GMD TECH COMPANY

Visit our exclusive sales partner SHENZHEN GMD TECH Company at this year's ‘PRODUCTRONICA China 2025’, which will take place from 26th to 28th March 2025 at SNIEC in Shanghai. Our booth with the number W4.218 awaits you there.

The ‘PRODUCTRONICA 2025 China’ is the leading trade fair in the field of production technology, automation and dispensing technology for the electronics industry, and offers an excellent opportunity to present the latest VISEC products and technologies.

Visit the booth of our partner SHENZHEN GMD TECH Company and learn first-hand about the innovative VISEC products that can optimise your manufacturing processes and workflows and increase efficiency. VISEC offers perfect dosing solutions even for the most difficult media and helps to improve processes, minimise downtimes and maintenance times and thus save time and costs. The competent staff of our sales partner will be happy to answer all your questions and give you an insight into our latest developments.

We look forward to meeting you at the trade fair in Shanghai. You can contact us or our partner at any time to make an appointment at the trade fair.

24th January 2025

Happy Lunar New Year.

We wish our business partners and customers in China, Asia and worldwide a healthy, prosperous and successful year 2025 - The year of the Snake.

Among other things, the snake is a symbol of wisdom. People born in the year of the snake are intelligent, wise, intuitive and build up strong relations and friendships.

We would also like to take these qualities with us into the new year in order to deepen our good business relations in China, Asia and worldwide and to achieve further joint successes.

18. December 2024

SEC / VISEC wishes you a Merry Christmas and a Happy New Year 2025

An eventful and challenging year is coming to an end and Christmas lies ahead of us.

We would therefore like to pause for a moment at Christmas time and thank all our customers and business partners from the bottom of our hearts for their trusting and successful cooperation.

We wish you and your families a peaceful festive season and a great start into the new year 2025.

‘The message of Christmas: There is no greater power than love. It overcomes hatred like light overcomes darkness. - Martin Luther King

31. October 2024

VISEC shaft seals - a success story

VISEC shaft seals have been in use at customers and projects for almost a year and a half, where they have been running without any problems and have therefore become an integral part of the VISEC product portfolio. The unique combination of chemical resistance and mechanical abrasion resistance enables a wide range of applications. The VISEC shaft seals master dispensing applications with chemically demanding adhesives as well as with highly filled and abrasive fillers (such as heat-conducting pastes) with flying colours and without difficulty. The service life and durability of the sealing rings are outstanding and fit seamlessly into the high quality and manufacturing standards of VISEC products (including rotors and stators). Thanks to innovative manufacturing processes and the newly developed sealing material hi-Q-seal, VISEC offers a complete solution for the ideal shaft sealing of PCP dispensers. Even under extreme continuous load, the wear of the shaft seals is extremely low and they are characterised by high resistance to chemicals, temperature and abrasive conditions.

VISEC shaft seals and O-rings complete the VISEC product range and offer the customer a system solution and package with which precise, gentle and demanding dispensing requirements can be perfectly realised.

02. August 2024

One solution for all dosing applications - Progressive Cavity Pump Technology

Process engineers and production planners are often faced with the challenge of defining and specifying the most suitable dosing solution. After all, this should run smoothly over a long period of time - ideally with as little maintenance and downtime as possible. In addition to the complex chemical structure of the media and adhesives, a number of other parameters must also be taken into account in the area of liquid dosing, such as viscosity, throughput, pressures, running times, hose lengths, supply, etc.

Those responsible are faced with the Herculean task of filtering out the best solution for their applications from countless dosing technologies and manufacturers, which can also fulfil the most important criteria, such as quality standards, cost optimisation, ease of integration and ease of maintenance.

For example, you can choose between piston technology, time-pressure systems, valve technology, gear pumps, peristaltic pumps, etc. All parameters of the application must always be checked in a difficult process. For example, the use of dosing technology depends very much on the viscosity. If the material is replaced by another, higher-viscosity material in the future, then in the worst case the entire dosing technology must be replaced, as this higher viscosity can no longer be processed reliably.

Every dosing technology has its justification, but also reaches its technical limits. However, one dosing principle stands out: the progressive cavity principle or PCP technology.

Thanks to the unique principle of volumetric dosing, even the most difficult media can be dosed without any problems. High viscosities, abrasive ingredients and shear-sensitive materials can be metered effortlessly. The dispensing volumes can be changed very easily by adjusting the drive speed, as the same volume is always dispensed per revolution of the dispenser.

VISEC develops and manufactures the core components (rotor, stator and shaft seals) of PCP technology. The latest findings, developments and materials are quickly integrated into the highest quality products.

Customers are offered the opportunity to implement their own dosing solution from these modular core components, which is optimally suited to their requirements and leads to perfect dosing results - true to the motto: One solution for all dosing applications.

16. Mai 2024

Trade show: BOND 2024 Shenzhen 2024 - The 5th Shenzhen International Dispensing Technology and Equipment Exhibition 2024

SHENZHEN GMD TECH COMPANY presents new innovations from VISEC

Visit our new exclusive sales partner SHENZHEN GMD TECH Company at this year's ‘BOND 2024 Shenzhen’, which will take place from June 26th to 28th,2024 at the Shenzhen World Exhibition & Convention Center. Our booth with the number 7B 21 awaits you there.

‘BOND 2024 Shenzhen’ is the leading trade fair in the field of dispensing technology, bonding, automation and systems, and offers an excellent opportunity to present the latest VISEC products and technologies.

Visit the booth of our partner SHENZHEN GMD TECH Company and learn first-hand about the innovative VISEC products that can optimise your manufacturing processes and workflows and increase efficiency. VISEC offers perfect dosing solutions even for the most difficult media and helps to improve processes, minimise downtimes and maintenance times and thus save time and costs. The competent staff of our sales partner will be happy to answer all your questions and give you an insight into our latest developments.

We look forward to meeting you at the trade fair in Shenzhen. For appointment requests at the fair, please contact us or our partner at any time (sales@sz-gmd.com)

01. Mai 2024

VISEC expands market presence and extends customer support in China

SHENZHEN GMD TECH COMPANY becomes VISEC's new exclusive partner

In order to ensure optimum support and assistance for Chinese customers, VISEC has gained SHENZHEN GMD TECH Company as its exclusive partner in China. GMD can draw on many years of experience, expertise and know-how in the field of dosing and offers the best technical support and assistance for customers in China. A perfectly developed network and branches in China guarantee the fastest support and customer proximity. VISEC Xiamen and existing customers and projects will be fully integrated into GMD. Competent employees and excellently equipped technical facilities at GMD (e.g. laboratory, test and trial equipment) enable the perfect VISEC dosing solution to be defined and implemented for the specific project or application.

VISEC is looking forward to the cooperation with GMD and can now respond even faster and more specifically to customer requests, react and offer technical support. For VISEC, the cooperation with GMD represents a further milestone in expanding its presence in China.

04. April 2024

Special rotor coatings for special requirements

The chemical compositions of adhesives, additives or special treatment or cleaning media in industry are becoming increasingly complex. By implementing the latest research results, the properties of these materials are continuously optimised and further developed. On the one hand, this improves the desired properties, such as faster curing mechanisms, better surface treatment, etc., but on the other hand, these materials and substances can in turn force reactions with other materials.

This poses a particular challenge for the dosing and application systems used. Due to new formulations or ingredients, existing dosing systems can no longer be used, or at least have to be modified in order to fulfil the requirements. Of course, this also applies to progressive cavity dispensers and systems. Where there were no problems in the past, these new adhesives cause enormous issues and even lead to complete failure of the dispensing system in some applications.

VISEC is focused on analysing these changed conditions (such as more demanding ingredients or new chemical formulations of the materials) and offering fast, flexible and successful solutions by adapting and further developing the dosing components.

One example concerns the new and special chemical formulation of a primer for surface treatment in the semiconductor industry. The manufacturer of this primer has perfectly adapted the composition with new ingredients to the application and the end product, but at the same time created major problems for the dosing system.

Standard dispensing components were no longer compatible and could no longer be used, as the primer reacts with metallic surfaces. Even the normally very inert and robust hard chrome-coated surface of the rotor of a progressive cavity dispenser reacts with the ingredients of the primer and causes material changes and wear of the rotor in the dispensing system. Even other special coatings react with the material and pose a major challenge to the dispensing system.

VISEC has taken on this problem, drawing on its decades of expertise and experience in the field of chemistry.

A specially developed coating and alloy (including gold particles) has proven to be the perfect solution for this difficult application. As a result, metallic particles from the rotor no longer react with the primer and, in combination with VISEC's hi-per stator (maximum chemical resistance), the primer can now be dispensed and applied to the electronic components without any issues.

VISEC focuses on customer orientation and problem solving. Through knowledge, experience and expertise, effective and uncomplicated solutions are offered and implemented as quickly as possible.

26. January 2024

VISEC - the innovative development partner

The principle of the progressive cavity pump has been known and invented for a very long time. It seemed that all developments and leaps in innovation had already been achieved for this technology. Nevertheless, VISEC has set itself the goal of continuously generating new solutions and ideas for the progressive cavity pump. Completely new approaches and concepts are developed, realised and brought to market maturity step by step. This proves that there are still numerous new development opportunities and improvements within the scope of progressive cavity technology.

VISEC is specifically focussed on implementing new ideas quickly, flexibly and successfully. Decades of expertise and experience in the field of elastomers and compounds make it possible to take completely new approaches and develop and test special mixtures or high-quality formulations, for example to significantly increase the service life of stators.

The aim is always to expand the advantages and benefits of this dosing technology for our customers and, for example, to minimise maintenance costs or downtimes. Innovative products help to consolidate and expand the position of progressive cavity technology as a high-end dosing technology.

VISEC is breaking new ground to get the best out of technology in the field of dosing applications. Last year, for example, the innovative 2R12-4eQ rotor/stator with its unique geometry was presented, as well as completely newly developed and high-quality shaft sealing rings.

This year will see further ground-breaking developments at VISEC and it will be interesting to see which solutions will be released and launched on the market step by step over the course of the year.

VISEC sees itself as a competent development partner for its customers, always on hand with help and advice and offering the best support and development expertise. The experts at VISEC are always available for this purpose.

18. December 2023

SEC / VISEC wishes Merry Christmas and a Happy New Year 2024

Time has flown by far too quickly and Christmas is just around the corner.

We would like to take this opportunity to thank you for the trust you have placed in us and the pleasant cooperation.

We wish all our customers, business partners and their families a peaceful and relaxing Christmas and a healthy and successful New Year 2024.

15. November 2023

Dispensing of abrasive & highly filled pastes (TIM material, thermal pastes, GAP-fillers)

The number of applications of dosing highly filled and abrasive pastes (often with a particle content up to 90 %) is increasing tremendously in the recent years. Especially the use of TIM (Thermal Interface Material) in the Electronics branch as well as in the EV-Industry (Electric Vehicles & E-Mobility) is getting more and more important. The TIM pastes and liquids guarantee a controlled heat transfer at electronic parts and batteries to ensure smooth and stable functions. Also, the risk of damages of these parts due to heat overload is being reduced by these special pastes. The recipes and quality of these materials have been improved during the recent years by adding special ingredients and additives. However, the most important ingredient is still a chemical reactive group with an excellent heat transfer rate. Typically, Aluminium Oxide or Titan Dioxide are used and mixed into these pastes. The feature of these chemicals is a very abrasive behaviour which is going to be a challenge for the dosing and dispensing system. At the same time, precision and accuracy are essential for the features of such electrical parts and battery modules.

The PCP-technology is offering the best solution for dosing of these challenging pastes and liquids. By using a special developed rubber mixture (hi-act) for the stator of the PCP-dispenser, in combination with a special coating of the rotor and drive shaft, VISEC offers a perfect solution to handle such highly abrasive pastes.

At the rotor and shaft side, VISEC has developed a special coating mixture and method to offer a very resistant and hard surface to withstand even extreme influences by very abrasive pastes and liquids. The dosing of such TIM material could be handled in a very smooth and accurate way.

The PCP-technology offers tremendous advantages and benefits when these TIM should be dispensed.

By using the PCP-technology an accuracy and repeatability of +/- 99% could be guaranteed. A clean and safe process will be ensured by the adjustable suck-back of the dispenser.

The special developed rubber material for the stators and coating of rotors extends the life time of the rotor to 4-5 times in comparison to a standard hard-chrome plated rotor assembly and even the life-time of the stator could be extended to 2-3 times compared to a stator with standard rubber.

VISEC is specialized in developing customized compounds for specific applications. Hi-act stator material is especially suitable for dosing applications with highly filled materials and abrasive particles. The features of this rubber compounds guarantee a smooth dispensing process for abrasive particles and the wear and tear of hi-act is quite small compared to other available rubber materials on the market.

Compared to solutions, where the rotor is made of ceramic, the coated rotor assembly offers a wide range of advantages: the surface of the coated rotor is also extremely hard and robust, but less expensive compared to ceramic material. The manufacturing process of the coated rotor itself, is much easier compared to the complex process of producing ceramic rotors. Also, at ceramic parts, there is always the risk of easy breakage and damage.

Due to the perfect combination of hi-act stator and special coated rotor, downtimes and long maintenance times could be avoided. Compared to competitor’s products, the life-time of these parts is much higher. This means less production interruptions, more process reliability and safety, higher quality standard and of course, less costs.

15. June 2023

Micro-Dosing of Solder Paste on PCB-boards and elements.

The dispensing of tiny dots or lines of solder pastes on PCB-boards is getting more and more important. Precision and accuracy are essential for the features of such electrical parts and components. Therefore, the PCP-technology offers tremendous advantages and benefits when these small volumes should be dispensed.

By using the PCP-technology an accuracy and repeatability of +/- 99% could be guaranteed. A clean and safe process will be ensured by the adjustable suck-back of the dispenser.

Typical solder pastes contain mainly metal particles (up to 90 %) and binder. The metal particles are extremely abrasive and are therefore really challenging the dispensing system. By using a special developed rubber mixture (hi-act), in combination with a special coating of the rotor and drive shaft, VISEC offers a perfect solution to handle such highly abrasive pastes. The life time of the rotor could be extended to 4-5 times in comparison to a standard hard-chrome plated rotor assembly and even the life-time of the stator could be extended to 2-3 times compared to a stator with standard rubber.

For applications on PCB-boards or other small and tiny electrical parts, the VISEC D03/UD03 rotor and stator combination, offers dosing quantities down to approx. 0.00025 cc. Smallest dot sizes of solder pastes could be dispensed without any problems.

VISEC is specialized in developing customized compounds for specific applications. Hi-act stator material is especially suitable for dosing applications with highly filled materials and abrasive particles. The features of this rubber compounds guarantee a smooth dispensing process for abrasive particles and the wear and tear of hi-act is quite small compared to other available rubber materials on the market.

At the rotor and shaft side, VISEC has developed a special coating mixture and method to offer a very resistant and hard surface to withstand even extreme influences by very abrasive pastes and liquids. The dosing of micro -dots of solder pastes could be handled in a very smooth and accurate way.

Compared to solutions, where the rotor is made of ceramic, the coated rotor assembly offers a wide range of advantages: the surface of the coated rotor is also extremely hard and robust, but less expensive compared to ceramic material. The manufacturing process of the coated rotor itself, is much easier compared to the complex process of producing ceramic rotors. Also, at ceramic parts, there is always the risk of easy breakage and damage.

Due to the perfect combination of hi-act stator and special coated rotor, downtimes and long maintenance times could be avoided. Compared to competitor’s products, the life-time of these parts is much higher. This means less production interruptions, more process reliability and safety, higher quality standard and of course, less costs.

VISEC offers the core components for PCP-dispenser and therefore tremendous advantages for companies, who intend to design and build their own units. By using existing components, like motor or control units this offers excellent synergy effects. The design of the PCP-dispenser could be adjusted, according to existing corporate design rules or requirements and provides the highest grade of flexibility.

24. May 2023

SEC takes another step towards becoming a system provider:

New: VISEC Accessories.

With shaft seals and O-rings specially adapted to the applications of the VISEC D- and R-series, SEC meets the requirements of the international market for high-performance metering for accessories of impeccable quality and readily available.

VISEC shaft seals meet the high demands on functional reliability and service life without restriction - even under extreme continuous load of VISEC stators and rotor units. Lowest possible wear due to high resistance to chemicals and temperatures are the primary advantages of VISEC shaft seals made of hi-Q seal.

SEC will successively expand its VISEC accessories portfolio in a customer-oriented manner and thus offer its partners efficient system solutions in the sense of "All-in-One" - for precise and gentle metering of of highly viscous media.

13. April 2023

Trade show: productronica China 2023.

We have great news for our customers and prospects in China! Visit our sales partner „VISEC(XIAMEN) TECHNOLOGY CO., LTD“ at this year's "productronica China", which will take place from April 13th to 15th, 2023 at the Shanghai New International Expo Centre (SNIEC). Our booth with the number W5.5852 is waiting for you there.

The "productronica China" fair is the leading trade fair for electronics manufacturing in Asia and an excellent opportunity to present our latest products and technologies. Visit us at our booth and learn firsthand how our products can help you optimize your production processes and increase efficiency. Our sales partner will be happy to answer all your questions and give you an insight into our latest developments.

We look forward to meeting you at the fair.

27. March 2023

VISEC takes of: With a strong partner on the American market.

The company "Air Flo Spray Equipment Company", which is active in the USA, has become a sales partner for VISEC with immediate effect. The aim of the cooperation is to further expand VISEC's presence in the American market and to serve customers even better through a sales partner from close proximity.

The Air Flo Spray and Equipment Company has been a major distributor of fluid transfer equipment used for lubricants, sealants, adhesives, inks and more for more than 50 years. Since 1965, Air Flo has been providing advanced dispensing equipment to customers throughout the United States of America.

Just like VISEC products, Air Flo stands for reliability, quality and efficiency.

28. February 2023

A geat innovation - VISEC 2R12-4eQ

With a real innovation, the VISEC R-series is extended by another Stator 2R12-4eQ and the corresponding Rotor unit UR12-4eQ.

Due to the unique and innovative 4-flight metering geometry, significantly higher flow rates and metering volumes can be achieved while maintaining the small size. The small space consumption as well as the relatively low weight prepare the new size "VISEC 2R12-4eQ" perfectly for automated applications and solutions, for example with robots and axis systems. This provides cost and investment savings for all VISEC customers. Smaller dimensioned robots can be used, which take up little space and thus represent low investment costs.

Thanks to the "VISEC Plus System" it is possible to use both sizes 3R12 and 2R12-4eQ in one and the same pump housing. Thus, a dosing volume of 2.30 ml/rev to 9.10 ml/rev can be covered within one pump environment. This increases efficiency and flexibility within the manufacturing process enormously.

With highest precision and dosing accuracy, the new size 2R12-4eQ is perfectly suited for feeding systems (e.g. drum emptying) or also for processing systems (e.g. degassing). The areas of application are very diverse and can be found, for example, in e-mobility, display bonding or also in electronics manufacturing.

26. January 2023

New sales partner in South Korea

VISEC wins the company Altech as a sales partner for South Korea. In close cooperation with SEC's German headquarters, Altech will expand sales of VISEC products on the South Korean market as exclusive sales partner with immediate effect.

As the fourth largest economy in Asia, Korea also offers very good market opportunities for VISEC. The quality demand on the South Korean market is extremely high. VISEC has already been supplying the Asian markets for several years. With the help of the new sales partner, it is now possible to respond and react to customer requirements even faster and more specifically.

As the potentials for VISEC products on the South Korean market are enormous, it is a real milestone to cooperate now with a sales partner on site.

23. December 2022

Merry Christmas & Happy New Year.

Christmas is almost here and an eventful year is coming to an end.

We would like to take this opportunity to thank you for the trust you have placed in us and the valuable cooperation.

We wish you a merry Christmas holiday and a healthy and successful new year.

20. June 2022

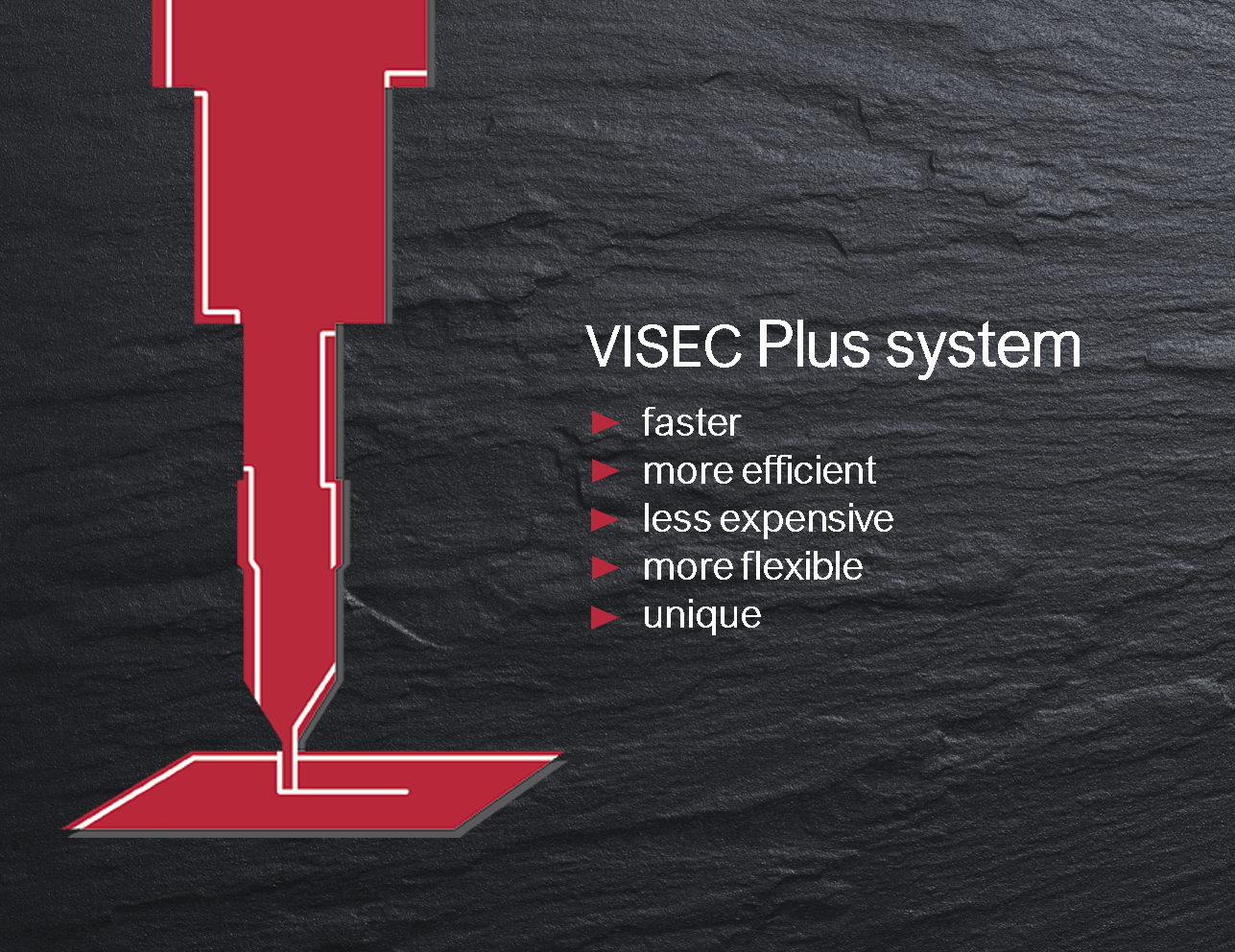

Simplifies production processes: The VISEC Plus system

With the VISEC Plus system, it is possible to use different VISEC Stators and Rotor units in one particular metering pump type. Due to the identical external dimensions of the components, it is therefore not necessary to make a design adaptation for each dosing volume.

For example, in the field of micro dosing, Stators and Rotor units of three different sizes (D03 micro, D15 micro and D45 micro) can be used in one and the same pump housing. This means that a metering volume of 0.003 ml/rev to 0.05 ml/rev can be covered for this type of pump.

This makes production processes faster and more efficient. Operators are able to react flexibly to the requirements of their markets and can save costs at the same time.

The VISEC Plus system is unique in the market for "high-performance dispensing systems".

23. March 2022

Trade mark registration in GB and Northern Ireland.

Since the withdrawal agreement between the EU and the UK came into force on 1 February 2020 (Agreement on the Withdrawal of the United Kingdom of Great Britain and Northern Ireland from the European Union and the European Atomic Energy Community, Official Journal of the European Union 2019/C384 I/01), the UK is in any case no longer a member of the EU.

It was therefore all the more important to register and thus protect the VISEC trademark in the UK and Northern Ireland.

VISEC was registered as a trade mark with effect from 21/09/2021 and finally entered in the register on 04/02/2022.

VISEC stands for precision, high quality and reliability. With these values we will continue to exploit the market potential in the UK and Northern Ireland in the future.

10. March 2022

The VISEC R-series is expanded.

The VISEC R series is being expanded with the new 3R12 Stator and the corresponding UR12 Rotor unit. With a flow rate of 2.30 to 276 ml/min, this Stator-Rotor combination is prepared for a wide range of applications.

In the development of this new size, it was particularly important that this system can be used both in the area of dosing and in the area of drum emptying. A high volumetric output is achieved with the best precision.

Especially in the field of dosing technology, very high precision is a prerequisite for an efficient and error-free process. With a repeat accuracy of over 99%, VISEC customers can fully rely on a smooth dosing process.

No matter in which areas the new "VISEC 3R12" is used, it convinces with precision, the usual VISEC quality, reliability and a high volumetric performance.

01. February 2022

Happy New Year.

We wish our Chinese business partners and customers a successful and good year 2022 - The Year of the Tiger.

Among other things, the tiger stands for strength, ambition, self-realization and courage.

We would also like to take these qualities with us into the new year in order to further strengthen our good business relations in China and to achieve further joint successes.

17. December 2021

VISEC wishes you a Merry Christmas and a Happy New Year 2022.

Especially in these turbulent times, we all appreciate the special value of reliable partnerships.

We would like to thank all customers and business partners for the trusting and successful cooperation this year and send you our warmest Christmas greetings this way.

We wish you and your families a wonderful Christmas season, good health and all the best for 2022!

23. June 2021

The perfect addition to the D-series

The new stator in the D-series convinces with an even smaller dosing volume than the previously smallest stator "VISEC D15 micro". With a minimum dispensing volume of approx. 0.00025 ml and a dispensing volume of approx. 0.003 ml per revolution, the new stator "VISEC D03 micro" perfectly complements and expands the VISEC product range in the field of micro dispensing technology. No other PCP system on the market is able to dispense these extremely small quantities.

Due to the special development of the stator-rotor system, a comparatively high pressure can be generated. This means that these very small quantities can be metered proportionally to the angle of rotation and without pulsation. With a repeatability of more than 99%, customers can rely on precise dosing from low- to high-viscosity media.

The new "VISEC D03 micro" stator has identical external dimensions to the two "VISEC D15 micro" and "D45 micro" stators. In combination with the respective matching rotor unit, these systems can be used in a modular way. With one and the same pump environment, it is thus possible to cover a wide range of metering volumes. This makes it possible to react flexibly and quickly to constantly changing market requirements.

No matter in which area of micro dispensing technology - whether in the production of electronic components, in optics and photonics, for plant manufacturers or in the field of application technology - the new "VISEC D03 micro" convinces with high quality, reliability and efficiency.

15. March 2021

Continuous improvement guaranteed - renewed certification according to ISO 9001:2015

With the renewed certification according to ISO 9001:2015, we prove once again that we continuously improve our products and processes.

In order to meet the high expectations of our customers, we have our quality, our qualification and our production processes regularly tested and monitored by an internationally recognized company - DQS.

With ISO 9001 certification, we guarantee our customers and partners services at the highest quality level and maximum process reliability.

In the area "Download / Service" you can download the latest certificate as PDF file in English.

26. January 2021

VISEC as a strong brand.

Since the launch of the VISEC product line in March 2019, it has already established itself as an independent brand. Since January 03, 2021, VISEC is now also officially registered as a trademark at the European Union Intellectual Property Office and thus protected.

The VISEC brand stands for high quality, reliability and precision. Taking these values into account, the products around the VISEC brand are constantly being further developed. In this way, the high demands of the market can be met and customers can rely on the best quality when purchasing a VISEC product.

16. December 2020

VISEC wishes you a Merry Christmas.

What a crazy year it has been. Corona has turned a lot of things upside down. However, it showed us that the crisis also makes us stronger. With our combined strength, we overcame the challenges and made the best of the situation.

Thank you for remaining loyal to us in this difficult year!

We wish you a peaceful Christmas and a healthy and successful New Year.

30. June 2020

The newcomer in the microdosing technology family.

With a dosing volume of 0.01 cc per rotation and a minimum dosing quantity of 0.0008 cc, the new stator "VISEC D15 micro" is the smallest in the D-series. With the specially developed elastomer compound "hi-tec", this stator is perfectly prepared for the exact delivery of a wide range of media under extreme conditions. The developed SEC formulation is, in addition to conveying oils, silicones and methyl acrylates, especially suitable for conveying cyanoacrylates.

Even before its market launch, the smallest unit was able to convince in practice with its high-precision, pulsation-free and material-friendly metering.

In combination with the perfectly matched rotor unit "VISEC UD15 micro", constant and precise dosing is possible. The thin and highly resistant elastomer compound "hi-tec" from SEC also provides optimum protection for this rotor unit, while at the same time ensuring flexibility of the rotor shaft.

The external dimensions of the new "VISEC D15 mirco" stator are identical to those of the "VISEC D45 micro". This allows to work with these two different sizes in the same pump. This creates flexibility within the production process and allows easy expansion of the possible dosing quantities.

For further information please refer to the product data sheets in the "Download / Service" section.

Exhibition China:

Visit our partner "VISEC/XIAMEN-TECHNOLOGY" at the productronica in Shanghai, China from July 03 to 05, 2020. Here you can inform yourself about all VISEC products and look forward to the product presentation of the new "D15 micro".

02. April 2020

We are here for you.

The health and safety of our employees, business partners and customers is our top priority. Therefore, due to the worsening corona pandemic, we have taken measures to prevent the spread of the virus as far as possible.

Nevertheless we are still available for you.

We are at your disposal as a reliable partner for all inquiries. In compliance with the important and necessary hygiene regulations, our services are still available to you.

03. February 2020

ISO 9001 : 2015

In order to meet the dynamic requirements of global competition, it is important to constantly increase efficiency and reduce costs.

By applying a quality management system, we ensure that SEC Compounds GmbH is continuously developing and attaches great importance to customer satisfaction. Therefore we were certified again according to ISO 9001 : 2015 in January 2020.

In the area "Download / Service" you can download the certificate as PDF file in English.

25. January 2020

To further success in 2020.

We wish our Chinese partners and customers a successful year 2020 - health and good luck in the Year of the Rat.

Last year we were able to further expand our partnership with our Chinese cooperation partner VISEC (XIAMEN) TECHNOLOGY CO., LTD. Due to the close cooperation we could already achieve success on the expanding Chinese market.

In 2020 we would like to further strengthen this successful cooperation in order to meet the customer requirements on the Chinese market.

18. December 2019

SEC wishes you a Merry Christmas.

Time has passed much too quickly.

Therefore we would like to pause for a moment at Christmas time and thank all our customers and business partners for the successful cooperation.

We wish you a happy holiday season and a successful and healthy start into the new year.

18. October 2019

VISEC shows colours on the Chinese Market

The VISEC sales partner XIAMEN TECHNOLOGY CO., LTD in XIAMEN-City and the headquarter of SEC in Germany decided to cooperate even closer: With effect of October 7th, 2019, the name of the newly founded company is „VISEC/XIAMEN- TECHNOLOGY”, the official sales partner for VISEC stators and rotors.

For the distribution of VISEC stators and rotors on the expanding Chinese market this is a further dynamic impulse. SEC is now able to follow the interests of Chinese customers and the trends in China even closer and can react faster to specific requirements.

Both companies, SEC and VISEC/XIAMEN TECHNOLOGY now have good basic conditions for a successful involvement in China.

31. September 2019

SEC starting Rotor Unit Program

SEC now offers precise VISEC Rotor units matching the VISEC Stators R- and D-series precisely. Our VISEC modules are the necessary precondition for a process-optimized increase of productivity – for example, by reducing setup times and improving the repeatability for high demands – also during long-term operation.

A special quality feature for permanent accurate application is the high-resistant elastomer compound “hi-per”, protecting the flexible shaft of the Rotor Unit efficiently.

VISEC Rotor Units are made in Germany on our premises and are subjected to strict quality control tests.

25. July 2019

Made to suit miniaturization of production processes

Miniaturization is the key to the future of automation. One of the main driving force in this direction is the electronic industry. The challenge for innovative bonding technology on minimum space is increasing constantly.

This trend began a few years ago with progressive evolution, which was one of the main reasons for SEC Compounds GmbH to bring stators and rotors of the VISEC D series for micro-dispensers to the market. Before introducing the modules D45 micro and D60 micro to the market, they proved their reliability after intensive testing with high-viscosity media.

The VISEC micro stators reach under extreme conditions and continuous use with short cycle operation times and minimal material quantities highest process reliabilities – with almost loss-free reproducibility.

In this context, the SEC elastomer compounds "hi-pro" and "hi-per" in the stators have a very essential function to ensure the quality. The especially designed SEC recipes for these compounds are prepared for accurate conveyance of adhesives, epoxy resins or heat-conducting paste with minimum wear of the stator. The VISEC components of the D series with minimal geometries give a significant contribution to this high productivity in different applications.

31. May 2019

High acceptance of stators and rotors of VISEC R-series

After the launch in March 2019, SEC Compounds GmbH registered a clearly positive response in the high-performance market for the VISEC 3R8 and 3R10 series adhesive technology.

Various customers have already successfully completed tests on our stators in conjunction with dispensers under operating conditions. First contracts are being concluded.

This success is based on the high degree of flexibility which stands for the VISEC stators and rotors while dosing with the highest volumetric accuracy. Even complex geometries in the smallest possible design can be realized with VISEC for dosing smallest quantities starting from 0,03cc.

It shows already that plant manufacturers and users have waited for these start-up products of the VISEC R-series -as an alternative to existing offers on the market- to concretise sustainable economic solutions.

On her production site in Germany, Baden-Wuerttemberg, is SEC well prepared to develop individual components within a short period of time and to provide requested high quantities in constant top quality.

04. March 2019

VISEC starts with high pressure

The market for dosing technology of highly viscous media has been clearly expansive in the last years. SEC Compounds GmbH, based in Kirchheim/Teck and leading manufacturer of rubber compounds for stators – the most important mechanical component of dispenser-systems – have been continuously observing this trend of a growing demand.

Beginning of March 2019 SEC launched their own program of stators and rotors under the brand name VISEC, designated for the international market. To start up, one series in each the standard- and the micro-segment is beeing offered.

Optimistic projections for SEC derive in particular from the longstanding expertise in technology-relevant elastomer compounds (hi-pro and hi-per), used in stators and being the key to their high reliability in permanent operation in a wide range of applications. With their solutions to the ever changing requirements of the market, SEC have successfully taken on all challenges and facilitated progress.

Seen from this angle, it’s an obvious step next to the standardized VISEC-series, the main focus of SEC lies in the development of customized solutions. Practice shows that especially multi-functionality, changed geometries of dispensers or new materials lay down new requirements for the innovation of stators. SEC contributes her knowledge, extensive know-how and strong performance power to all projects.